I've fired it up 3 times, I did say, a couple of posts ago, that it was fully operational. That kinda suggests I have tried it, lol.

I'll put the figures up after my next trip 4x4ing, but for now.....

When first started it pulls about 10A when the glo pin is on, that's only for 3 or so minutes. The blower fan ramps up like a jet turbine to raise the temp in the van and seems to pull about 2.8A. How long this goes for depends on the ambient temp, the temp in the van and the temp I set the heater to go to. I'll post actual data when I go out in a month or so. The van battery will be in actual conditions not in my driveway.

Tonight the ambient inside the van was 11 deg, (it was colder outside) I set the heater to 17 deg and it took about 30min to get there. Once at temp the fan slows down to a low hum to maintain temp. At this point it pulls 0.8A

So for now I guestimate that if I switch on at 7pm and turn off at 8am (13 hours) A 1 hour start up using 3A, I will use roughly 12-13AH overnight and about 1.5 to 1.7 litres of diesel.

My LED lighting (what I use I rate at 1.5A per hour average) from say 6pm to midnight will use 9AH. Plus the TV @ 2.8A for 4 hours = 11.2A

TV and light use is maximum and more often less, so my total above in 24hrs is about 33AH. I have a 120AH AGM so I'm on track to maximise battery life @ 25% use of capacity.

I'll see how close I get when away, I will be off power and only using solar and or my car to charge.

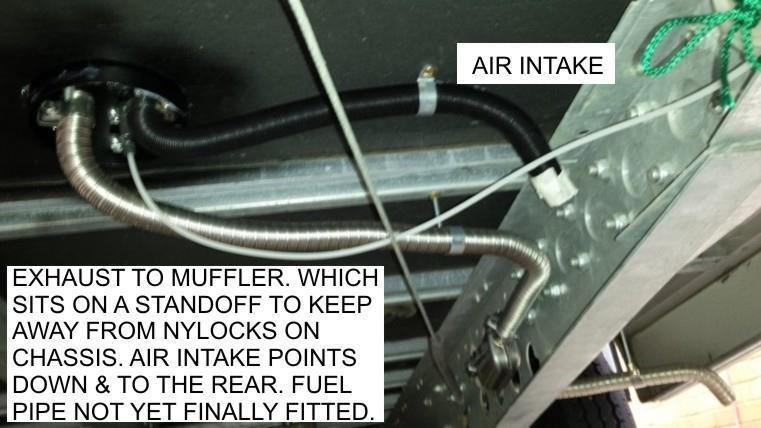

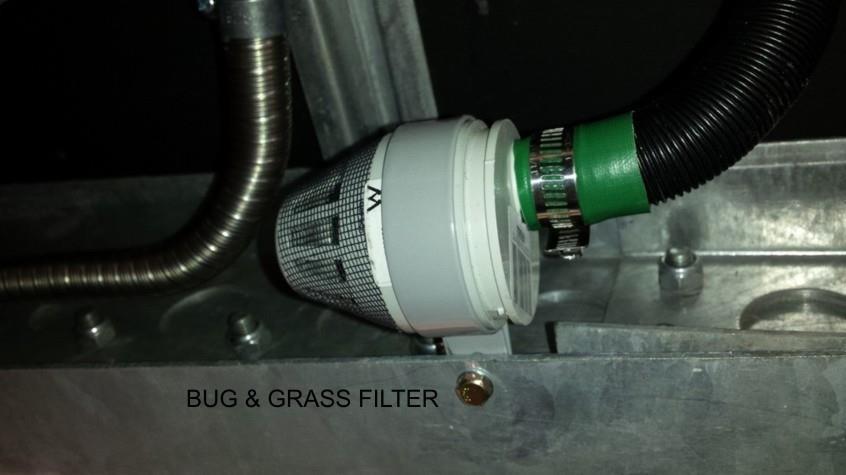

And, yes I have checked for leaks, but I've noticed when on high the combustion air intake seems to whistle. This maybe the improvised bug filter, but once the heater slows down, it disappears.