Hay DWT,

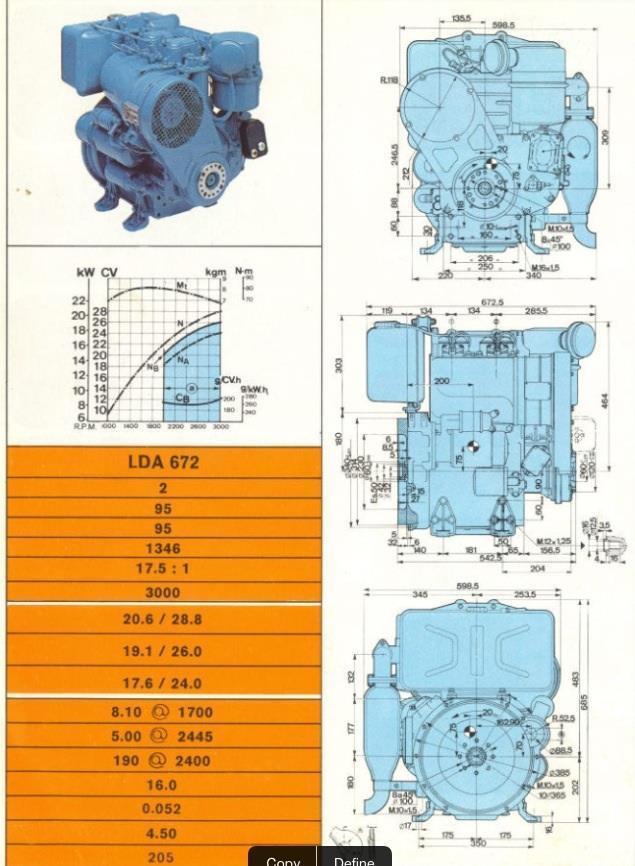

Free air delivery is swept volume x rpm. swept volume is bore x stroke.

Just looking at the size of the cylinder it looks about 500cc which would put it about 1000 l/min assuming 2000 rpm which is about 35 cfm at a very very rough guess.

Or you could do it the scientific way, this will give you the actual CFM at working pressure, not unloaded free air delivery.

1 Determine the volume of your air compressor tank in gallons. This should be clearly marked on the tank itself by the manufacturer.

2 Divide the tank volume by 7.48 (7.48 equals the number of gallons in one cubic foot.) The number that you get after the division is the tank volume expressed in cubic feet.

3 Release the air from your compressor.

4 Begin refilling the compressor with air. Record the amount of time that it takes to refill the tank while paying close attention to the compressor's tank gauge. You will need to record the psig (pounds per square inch) at two separate times in the refill process: once at the moment the compressor kicks in and once at the moment the compressor kicks out.

5 Take the psig indicated on the compressor's tank gauge when the compressor kicked in and subtract it from the psig indicated when the compressor kicked out. For example, if the compressor kicks in at 75 psig and kicks out at 100 psig then the difference would be 25 psig.

6 Divide the difference between the two recorded psigs by 14.7. The result will give you the amount of pressure added during the tank's filling cycle in terms of atm (atmospheric pressure).

7 Take the volume of the tank expressed in cubic feet (calculated in Step 2) and multiply it by the amount of pressure added during the tanks filling cycle in terms of atmospheric pressure (calculated in Step 6). This is the number of cubic feet that your compressor pumps in the time it took for your tank to fill (recorded in Step 4).

8 Convert this number to minutes. To do this, take the number of cubic feet found in Step 7 and divide it by the number of seconds it took to pump this amount. Multiply the result by 60 and you have the CFM of your air compressor.