Well done on finding ya digger mate.

Mackka

Mackka

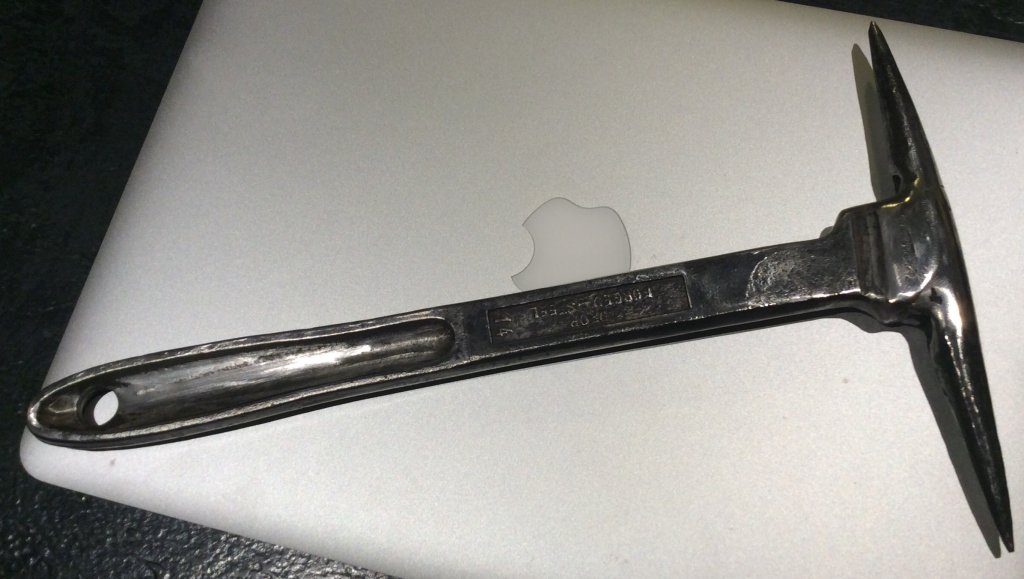

OzzieAu said:Hi RM... no cast, just old good quality forged steel, easy as to weld with my 40yr. old dinosaur arc.

I cant weld cast or galv for nuts... dont know about special rods either... I went to trade school a lo...oong time ago :lol:

Jaros said:Good job RM.

OzzieAu said:Hi RM... no cast, just old good quality forged steel, easy as to weld with my 40yr. old dinosaur arc.

I cant weld cast or galv for nuts... dont know about special rods either... I went to trade school a lo...oong time ago :lol:

Yeah I see what you mean Muk..... better watch the backswingMuk said:Looks good Ozzie dont poke a hole in your forod with it cheers Muk.

Wishfull said:OzzieAu said:Hi RM... no cast, just old good quality forged steel, easy as to weld with my 40yr. old dinosaur arc.

I cant weld cast or galv for nuts... dont know about special rods either... I went to trade school a lo...oong time ago :lol:

Cast isnt hard to weld. Use cast rods. Heat the metal first then weld it but, Do Not let it cool very quickly at all. Wrap it in something like welding gloves and cover with a bag or put it in lime or sand and let it cool for at least 15 minutes. If it is a thick piece you should peen it, meaning tapping it with an engineers hammer on the welds using the rounded part and then very gradually cooling it.

But I could be wrong

Galv grind off the galv and weld it. Fumes are really nasty. Just ask me.

Enter your email address to join: