You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

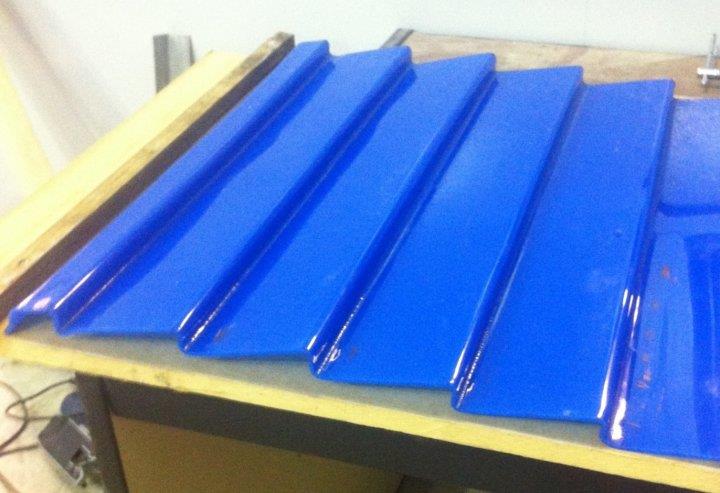

Progress with my drop riffles

- Thread starter Tommtb7

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

WalnLiz

Wal nLiz

Looking good there Tom....Might get you build some new steps for the caravan when you finish that project,

Cheers Wal.

Cheers Wal.

Tommtb7

Tommy

- Joined

- May 25, 2013

- Messages

- 103

- Reaction score

- 23

Haha I could do that wal but they won't come with a warranty lol. hi nugget, we'll you may of seen my highbanker in other posts on the forum but basically what I'm doin is adding a removable extension for drop riffles, I already have Hungarian riffles with moss and ribbed matting, I figured if I have expanded mesh then angled bar then drop riffles then that will increase my chance of retaining flour gold, the extension flares out to drop the water pressure so the material can gently roll down and do what they do best, I'm not to sure if it will work but I thought I would give it a go.

Tommtb7

Tommy

- Joined

- May 25, 2013

- Messages

- 103

- Reaction score

- 23

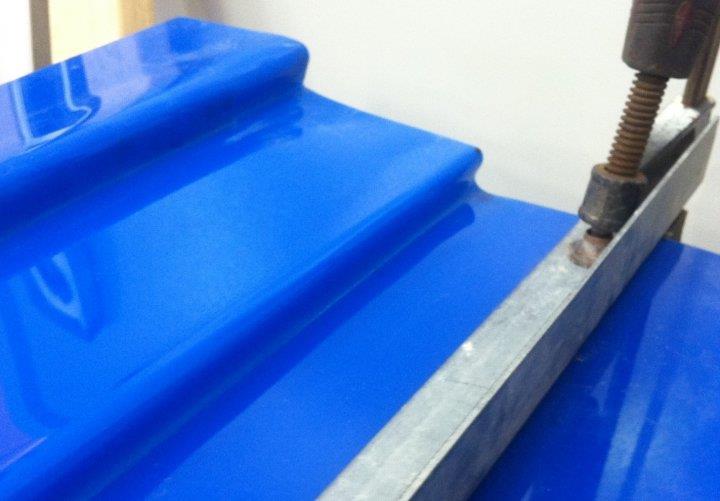

I heat the sheet with a heat gun, the sheet is from bunnings it was $45 and the heat gun I already had but bunnings have them for $30 (I'm a fan of bunnings) then I got a road sign from a recycling emporium which I think is a fancy name for a junk yard. I scored the aluminium road sign with a grinder along the fold marks then just bent it to form a channel with 90 degree bends I made the bends on angles down the entire length to get a flare to drop the water pressure to suit the drop riffle design so if you were looking at it from birds eye view it would look \^/ the arrow shows water direction

G

Guest

DIY plastic sluice, This place and its members never cease to amaze me.

- Joined

- Nov 27, 2012

- Messages

- 6,020

- Reaction score

- 1,975

Tommtb7 said:I heat the sheet with a heat gun, the sheet is from bunnings it was $45 and the heat gun I already had but bunnings have them for $30 (I'm a fan of bunnings) then I got a road sign from a recycling emporium which I think is a fancy name for a junk yard. I scored the aluminium road sign with a grinder along the fold marks then just bent it to form a channel with 90 degree bends I made the bends on angles down the entire length to get a flare to drop the water pressure to suit the drop riffle design so if you were looking at it from birds eye view it would look \^/ the arrow shows water direction

Wow, you're a creative fella aren't you :lol:. I'm looking forward to seeing the end result.

Nugget.

- Joined

- Jan 6, 2013

- Messages

- 1,072

- Reaction score

- 566

Looking good Tom!

I'm wondering if a little trap area at the bottom of each drop would be good, so when you turn the water off it doesn't surge or suck out the heavies?

With a MacKirk, you lift out the sluice so the heavies don't move.

Would only need to be a shallow channel - say 3-4mm deep & 5mm in width & my thinking, wouldn't take too much to mold in hmmm...

Just thinkin out loud

I'm wondering if a little trap area at the bottom of each drop would be good, so when you turn the water off it doesn't surge or suck out the heavies?

With a MacKirk, you lift out the sluice so the heavies don't move.

Would only need to be a shallow channel - say 3-4mm deep & 5mm in width & my thinking, wouldn't take too much to mold in hmmm...

Just thinkin out loud

Similar threads

- Replies

- 0

- Views

- 132

- Replies

- 8

- Views

- 3K

- Replies

- 2

- Views

- 1K

- Replies

- 2

- Views

- 3K

- Replies

- 40

- Views

- 3K