DigginForGold

Matt

Hello

So I purchased a 3D printer that will be hopefully arriving by the end of the week, if not early next week.

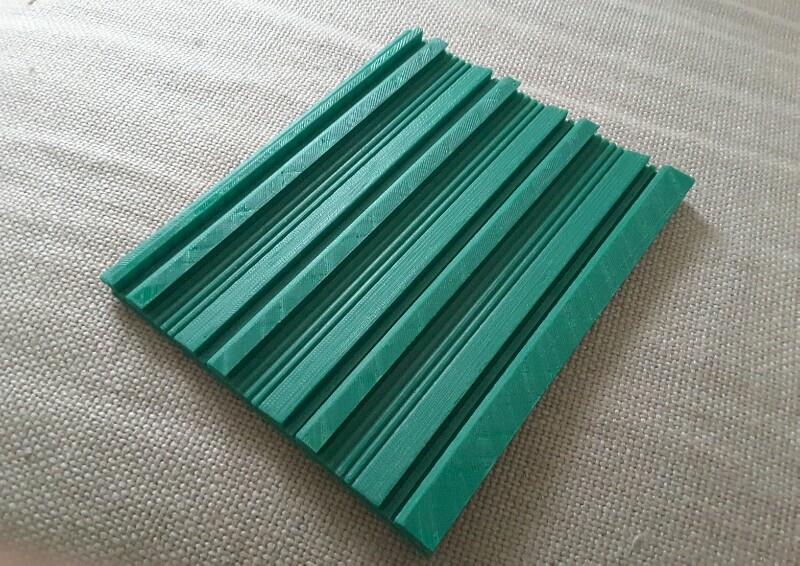

Ive been doing a little 3D modelling on the ol computer in the meantime and decided to try and replicate one or two of the Gold Hog mats just for the fun of it. I ended up copying the Talon, Bedrock 2.0 and DownDraft mats.

I got them mostly the same, but there is some slight variation since I didnt have any actual matting to get measurments from or anytning. Now I dont know a lot about Gold Hog mats but it seems to me like they're fairly precisely engineered. But how much so? Is 1mm here of there going to make a lot of difference or render the mat useless? Check the pics below to see how mine compare to the originals.

I figure they might be worth a shot in my highbanker since its under 190mm wide so I will be able to print out wide enough sections. And since it'll cost me $25 instead of $130+ to try these three mats I wont lose too much should it not work out. And I'll print em out in green so I'll be able to see the black sands much easier than on the black.

Im not really sure if copying and printing this out is 100% legal, but whatever. I dont really care lol. They're not EXACTLY the same, and Im not selling them or anything so yeah.

So here are the profiles. The black ones are the orginals, the white ones are mine. What do you think...close enough? I reckon the Bedrock and DownDraft (the first two) might be alright...

So I purchased a 3D printer that will be hopefully arriving by the end of the week, if not early next week.

Ive been doing a little 3D modelling on the ol computer in the meantime and decided to try and replicate one or two of the Gold Hog mats just for the fun of it. I ended up copying the Talon, Bedrock 2.0 and DownDraft mats.

I got them mostly the same, but there is some slight variation since I didnt have any actual matting to get measurments from or anytning. Now I dont know a lot about Gold Hog mats but it seems to me like they're fairly precisely engineered. But how much so? Is 1mm here of there going to make a lot of difference or render the mat useless? Check the pics below to see how mine compare to the originals.

I figure they might be worth a shot in my highbanker since its under 190mm wide so I will be able to print out wide enough sections. And since it'll cost me $25 instead of $130+ to try these three mats I wont lose too much should it not work out. And I'll print em out in green so I'll be able to see the black sands much easier than on the black.

Im not really sure if copying and printing this out is 100% legal, but whatever. I dont really care lol. They're not EXACTLY the same, and Im not selling them or anything so yeah.

So here are the profiles. The black ones are the orginals, the white ones are mine. What do you think...close enough? I reckon the Bedrock and DownDraft (the first two) might be alright...