how thick is the dream mat if it is ok to ask, the chopping board stuff we used to use was around 12mm thick, but for the life of me can not remember where we got it from

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Dream mat in a Walbanker

- Thread starter bundyjd

- Start date

Help Support Prospecting Australia:

This site may earn a commission from merchant affiliate

links, including eBay, Amazon, and others.

I use a thin blade razor knife and soapy water to cut conveyor belt matting. Also

this system is used to remove a windscreen from a modern car. Yes, They are glued in with

high strength, High Bond Urethane.

I am about to order some for my bankers and this is how I am going to do it.

For the Walbanker,

First, Make a cardboard template that is cut to suit the angles of the hopper.

Transfer the outline onto the back of the Dream Mat.

Using a piece of Aluminum flat as a guide, Spray some really soapy water onto

the matting and then draw the knife along the guide.

Be careful you don't break the knife and cut one of your fingers off.

You could also use a Stanley type knife that has a stronger blade for safety.

.

For my little banker I will do the same thing but will have angle glued onto the edges

as I have designed it to have removable cartridges.

.

Dustin Please correct me if I am wrong mate. LOL

this system is used to remove a windscreen from a modern car. Yes, They are glued in with

high strength, High Bond Urethane.

I am about to order some for my bankers and this is how I am going to do it.

For the Walbanker,

First, Make a cardboard template that is cut to suit the angles of the hopper.

Transfer the outline onto the back of the Dream Mat.

Using a piece of Aluminum flat as a guide, Spray some really soapy water onto

the matting and then draw the knife along the guide.

Be careful you don't break the knife and cut one of your fingers off.

You could also use a Stanley type knife that has a stronger blade for safety.

.

For my little banker I will do the same thing but will have angle glued onto the edges

as I have designed it to have removable cartridges.

.

Dustin Please correct me if I am wrong mate. LOL

bundyjd

John

I'm going to try an 8" mat so cutting the mat isn't an option. It should fit snugly at the bottom of the sluice (in fact may need a bit of a haircut to sit flat, as it's a shade under 8 inches), but will leave some gaps at the top of the mat due to the tapered channel - hence the original question about how to fill it.

The mold idea sounds good Golddigg@, although I'm not sure how many walbankers would be the exact same dimensions....

The mold idea sounds good Golddigg@, although I'm not sure how many walbankers would be the exact same dimensions....

sorry fellas i'm a little buried still playing catch-up from a week of hospital visits.

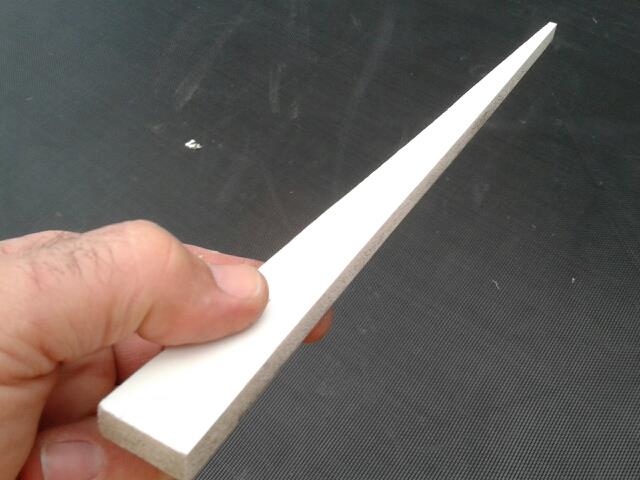

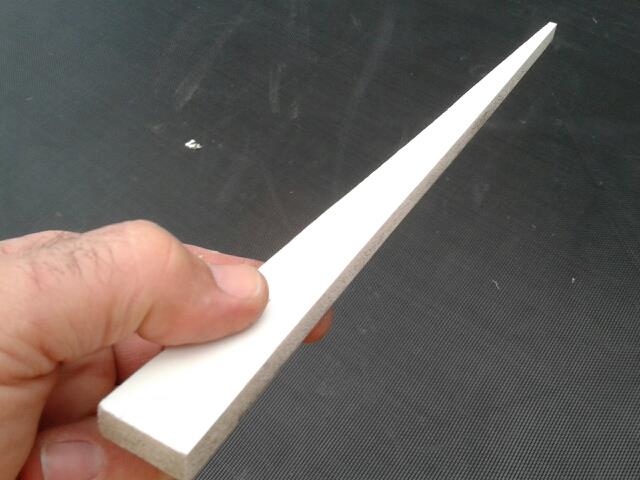

the issue is not are you able to cut it its more the pull, so with a soapy knife and a smooth slow hand you can get through it its just not the best outcome when you cut the into the cells. as for a grinder it will fill a room with smoke in a heartbeat again its cut and tear resistance is extreme its designed to repel water and be hammered by sand and gravel all day. the above piece was cut within 1 day of cast as its still hasn;t formed a crystalline structure.

the original question though is how to bumper up to a full mat not how to cut a mat, weve got a little off topic here bundyjd doesn't need to cut the mat at all.

bundyjd doesn't need to cut the mat at all.

the issue is not are you able to cut it its more the pull, so with a soapy knife and a smooth slow hand you can get through it its just not the best outcome when you cut the into the cells. as for a grinder it will fill a room with smoke in a heartbeat again its cut and tear resistance is extreme its designed to repel water and be hammered by sand and gravel all day. the above piece was cut within 1 day of cast as its still hasn;t formed a crystalline structure.

the original question though is how to bumper up to a full mat not how to cut a mat, weve got a little off topic here

Few tubes of silastic seems to be the easiest, 50mm builders tape on mat edge, just over fill on sluice wall and smooth off an angle down to the mat with a wet finger. Need rag to clean finger, and keep it real wet.

PT73

PT

Here's the plastic sheet I mentioned to resolve a similar issue. I am lucky enough to have several decent off-cuts from a signage job. Used for all sorts of applications though. Really tough stuff.

bundyjd

John

Thanks for the offer PT73, much appreciated.

I finally got around to fitting the dream mat today. I had a gap of about 18mm either side of the mat at the upper end, the mat itself is about 13mm thick.

Walked into Clark Rubber and found a length of 18mm x 13mm rubber strip. Well I'll be buggered.

Sandwiched it between a couple of bits of scrap timber screwed to the bench and cut it into long wedges with a straight edge and a new box cutter blade.

The end result.

I used the long aluminium arms that held down the original internals to hold down the strips, and the clamp to hold the top of the mat. You can see it a bit better here.

Now if it could just stop friggin' raining.....

I finally got around to fitting the dream mat today. I had a gap of about 18mm either side of the mat at the upper end, the mat itself is about 13mm thick.

Walked into Clark Rubber and found a length of 18mm x 13mm rubber strip. Well I'll be buggered.

Sandwiched it between a couple of bits of scrap timber screwed to the bench and cut it into long wedges with a straight edge and a new box cutter blade.

The end result.

I used the long aluminium arms that held down the original internals to hold down the strips, and the clamp to hold the top of the mat. You can see it a bit better here.

Now if it could just stop friggin' raining.....

Came up awesome mate

Just think of all the new yella coming down the gullies and creeks-just for you!!

- Joined

- Oct 23, 2016

- Messages

- 4

- Reaction score

- 6

Can this dream matting be ordered in wider lengths or is this the only size available. Looks real nice non the less. I am going to get the mountable level and the inclinometer, that looks like it will make setup a breeze.

Bill Jeffries

Bill Jeffries

- Joined

- Jul 20, 2016

- Messages

- 2,274

- Reaction score

- 2,271

Looks like he makes an 8,10 and 12 inch wide.

http://highbanker.com.au/collections/all

http://highbanker.com.au/collections/all

Spot on currently casting 8 10 and 12 inch by 36. A combination of these varies widths i.e 2x8=16 etc.

G0lddigg@ said:Spot on currently casting 8 10 and 12 inch by 36. A combination of these varies widths i.e 2x8=16 etc.

G'day Dustin,

be sure to let us know if you are planning a 4 inch casting....

casper

hey Casper short answer is yes mate, there will be a whole range of great products to support the cells technology i'll leave it at that for now

welcome news for many I'm sure.......

PT73 said:I agree with Limpalot. Jigsaw it. Reasonably simple, although I have not cut a dream mat, I use this trick often to get straight cuts on a whole range of materials...

1. Mark your taper lines on the reverse of the mat with a marker.

2. Get hold of a solid bit of straight edge, such as angle or flat bar.

3. Measure the distance from your jigsaw blade (the centre) to the edge/side of the jigsaw base plate. My distance is about 35mm.

4. Measure from your marked line in (in my case 35mm). Use the bench and clamp down your straight edge at this point on the mat. You could use some screws also to keep it nice and straight in the middle.

5. You now have a guide to run the jigsaw along. Test that the blade meets the line you marked. Take your time and cut slowly.

6. Voila! there you have a neat, straight cut.

I would recommend using a blade similar to a hacksaw for metal cutting or try to get a thinner blade recommended for plastics. Don't go too quick, you don't want it to melt!

This is off topic but briefly cutting a Dream Mat is a considerable challenge as it resists even the sharpest blade, a jig saw simply tears the material. Perserverance will produce a result but not one you'd likely not be happy with. I have cut it successfully and are happy to discuss elsewhere.

casper

- Joined

- Oct 23, 2016

- Messages

- 4

- Reaction score

- 6

Might I recommend going to a sheet metal shop and have them shear it to what ever size you want.

Bill

Bill

Won't sheer well mate. Best result to date has been water lazer cut but even thats slow as buggery and expensive

bandmenter said:Might I recommend going to a sheet metal shop and have them shear it to what ever size you want.

Bill

That is what I used - I have access to one where I work and had a play with it during my lunch break a couple of weeks ago.

It can shear well but often doesn't so far 1 out of every 3 or 4 cuts goes wrong for a variety of reasons that I'm working thru and I,m still developing a technique but I'm quietly comfortable that it will be able to be cut reliably.

Here's my efforts so far....

and a dud...

casper

Similar threads

- Replies

- 0

- Views

- 307

- Replies

- 13

- Views

- 2K

- Replies

- 5

- Views

- 3K

- Replies

- 7

- Views

- 4K