thought id put up some non bias info re the compact crusher so you members can have a scars and all look at what it does. Remember this is not a "rock crusher" parse its for sampling not belting tonnes of rock through.

I ordered on of Ryan's crushers for home sampling paid for it 4pm arrived 7.30am next morning with Austpost thanks Ryan.

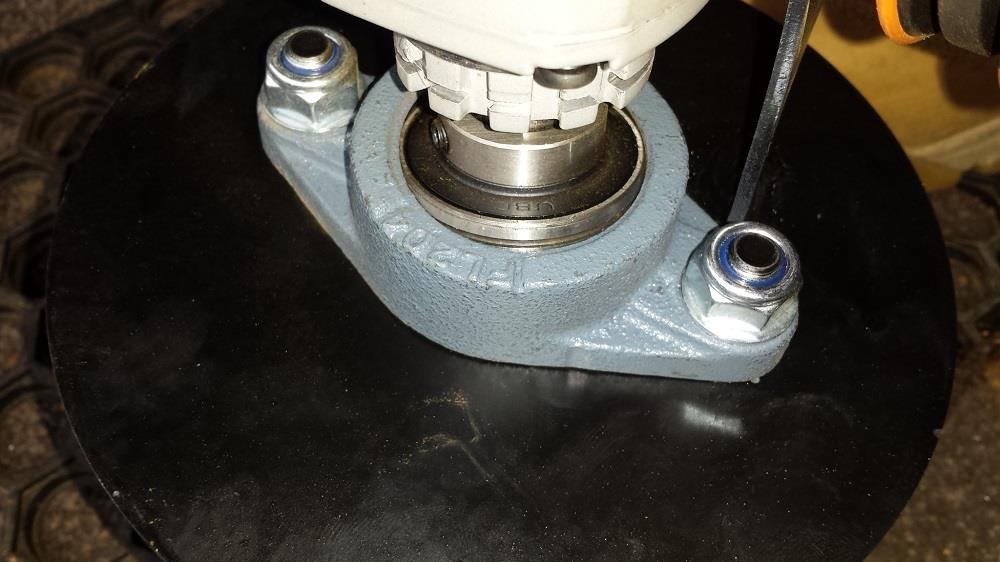

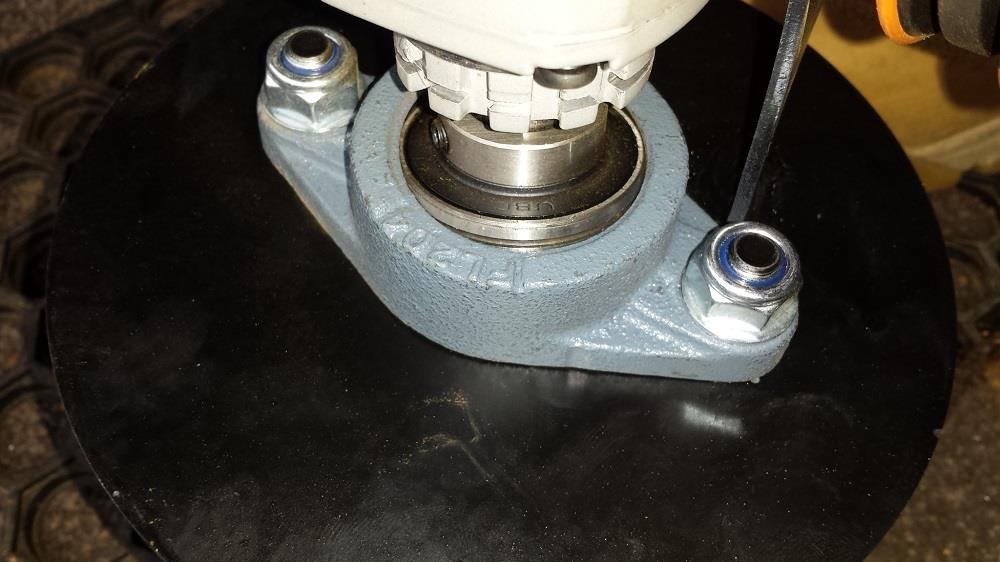

First glance was surprised to open the box fully assembled ready to go, so I chucked some rocks through silly me I should have had a play first to see that everything was straight. anyway there was a bit of play in the mounting of the grinder, no problem i will strengthen the mount later, in the meantime make sure its nice and flat before you run any rocks. i clamped it into bench vice.

So my first grind was a mess lots of metal lots of noise I worked out that some of the weld had to be knocked off before i'd have a clean grind. Additionally the bolts inside were being hammered by the chain, I believe Ryan will be using all thread for this in the future rather than bolt heads.

The second issue was the wing nuts coming off under load, another easy fix i put some rubber on them it takes the impact out of the nut.

Now once i had this thing dialed in it ran like a dream. no heat coming off the grinder, no noise no metal just purred away like a grumpy cat.

Well onto my next issue, I plan to use the tool mostly in my shed so the dust banging around just wasn't going to cut it, the issue is with the only pressure outlet being the inlet you open everything up to fill the room with dust every time you feed some rock. This would not be an issue in the field as its intended but for me i got to cutting and modding cos I'm a tinkerer.

I made a very simple outlet to release the pressure and dampen the dust as it comes out. I tried a rubber seal originally but that didn't work too well so a door dust seal now seals quite well. as you can see in the last two pictures there's no dust anywhere - i took this photo with the crusher running. very happy with the mod and I will soon make a small metal base for the rock crusher to sit on.

By the way adding the hose at the end made a huge difference for damping the dust spread

If you are thinking about buying one of these I can attest to the fact that the components here are solid and made with quality workmanship, dust in the face aside they run right out of the box, just let them wear in a little. Great buy for my money

I ordered on of Ryan's crushers for home sampling paid for it 4pm arrived 7.30am next morning with Austpost thanks Ryan.

First glance was surprised to open the box fully assembled ready to go, so I chucked some rocks through silly me I should have had a play first to see that everything was straight. anyway there was a bit of play in the mounting of the grinder, no problem i will strengthen the mount later, in the meantime make sure its nice and flat before you run any rocks. i clamped it into bench vice.

So my first grind was a mess lots of metal lots of noise I worked out that some of the weld had to be knocked off before i'd have a clean grind. Additionally the bolts inside were being hammered by the chain, I believe Ryan will be using all thread for this in the future rather than bolt heads.

The second issue was the wing nuts coming off under load, another easy fix i put some rubber on them it takes the impact out of the nut.

Now once i had this thing dialed in it ran like a dream. no heat coming off the grinder, no noise no metal just purred away like a grumpy cat.

Well onto my next issue, I plan to use the tool mostly in my shed so the dust banging around just wasn't going to cut it, the issue is with the only pressure outlet being the inlet you open everything up to fill the room with dust every time you feed some rock. This would not be an issue in the field as its intended but for me i got to cutting and modding cos I'm a tinkerer.

I made a very simple outlet to release the pressure and dampen the dust as it comes out. I tried a rubber seal originally but that didn't work too well so a door dust seal now seals quite well. as you can see in the last two pictures there's no dust anywhere - i took this photo with the crusher running. very happy with the mod and I will soon make a small metal base for the rock crusher to sit on.

By the way adding the hose at the end made a huge difference for damping the dust spread

If you are thinking about buying one of these I can attest to the fact that the components here are solid and made with quality workmanship, dust in the face aside they run right out of the box, just let them wear in a little. Great buy for my money