G

Guest

hahah right?!

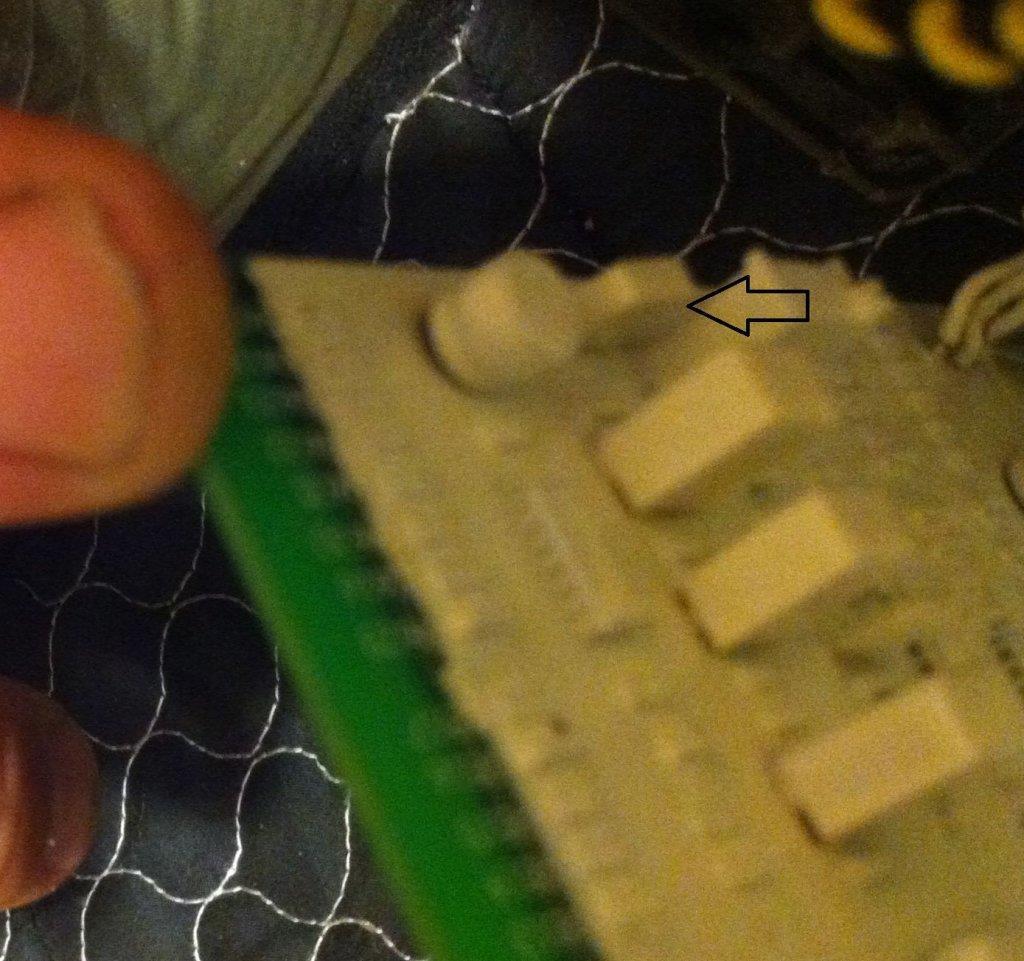

LazyTrommel said:It is a capacitor, if you carefully scratch off the pain you 'should' be able to get a part number off it.. (if ML haven't removed it)

You could also de-solder the cap, tap the broken leg with a wire, hot glue the cap to the board, and tack the wire to the pad on the board (dodgy but effective)

-LT

rs-components digikey (maybe Jaycar) will have a replacement...

It works, use it carefully though, some of that crap is corrosive..mozzie1957 said:LazyTrommel said:It is a capacitor, if you carefully scratch off the pain you 'should' be able to get a part number off it.. (if ML haven't removed it)

You could also de-solder the cap, tap the broken leg with a wire, hot glue the cap to the board, and tack the wire to the pad on the board (dodgy but effective)

-LT

rs-components digikey (maybe Jaycar) will have a replacement...

Thanks LT. All the white paint is a pain. Paint stripper?

mozzie1957 said:LazyTrommel said:It is a capacitor, if you carefully scratch off the pain you 'should' be able to get a part number off it.. (if ML haven't removed it)

You could also de-solder the cap, tap the broken leg with a wire, hot glue the cap to the board, and tack the wire to the pad on the board (dodgy but effective)

-LT

rs-components digikey (maybe Jaycar) will have a replacement...

Thanks LT. All the white paint is a pain. Paint stripper?

AuMan said:Hi Mozzie,

That cap you broke is a 47uf 16v. Try and get a short one at they foul with the ferrite on the coil plug. The + side is closest to the edge of the board.

Don't use paint stripper, it is bad stuff and goes under the components and can cause headaches later on down the track.

Lt, please explain how you snap off a 10 turn trim pot?!

AuMan

AuMan said:Use some hot air from your hot air solder station to heat the board and assist in the removal of through hole components. They normally fall out.

Yes I know exactly what that pot does...

AuMan

KarlS said:Just use bit more solder on the solder joint. Make sure that your soldering iron is not too hot, about 300 degree C or bit less. After heating the joint and componend leg for about 3 to 4 seconds you can pull the component out. Then clean up with solder wick. Unheated solder suckered aren't much good to clean holes. Do same with SM chips. Run the solder across the pins and to short them out. It require bit of juggling to have molten solder on both sides of IC . You can use two soldering irons for that . Most important is that the soldering iron is not too hot.

Karl

Enter your email address to join: