Yeah Nah. The GF4 handpiece does not fit by any stretch.

So back to the drawing board.

Now is the time to close this page because I'm about to have a major winge.

Wally69 said:

Well done on the diagnosis Badge.hope you have the 3 springs.

With your iPhone use the 2x zoom only to take a photo as the pixel count is reduced for anything else. Use the edit tool to zoom in on your stones after that to enlarge the them in the photo. Sometimes getting the right focal point is difficult and an inanimate object nest to the stone to focus on will help.

Well I thought you were joking about the springs but when I finally removed the third ball bearing to put in a new one a squashed up little spring came with it. I should have known you would be right. I put in 3 new ball bearings but without the spring that was all squashed up and mangled the handpiece wouldn't lock into place.

So the other two were running without a spring, as was the squashed one. I tried putting 2 ball bearings in to see if that would help but without the springs to reduce tension the handpiece is useless.

As it is the handpiece has a slop and it and only slops when approaching index 64. But it had that already.

Hoping the pics turn out.

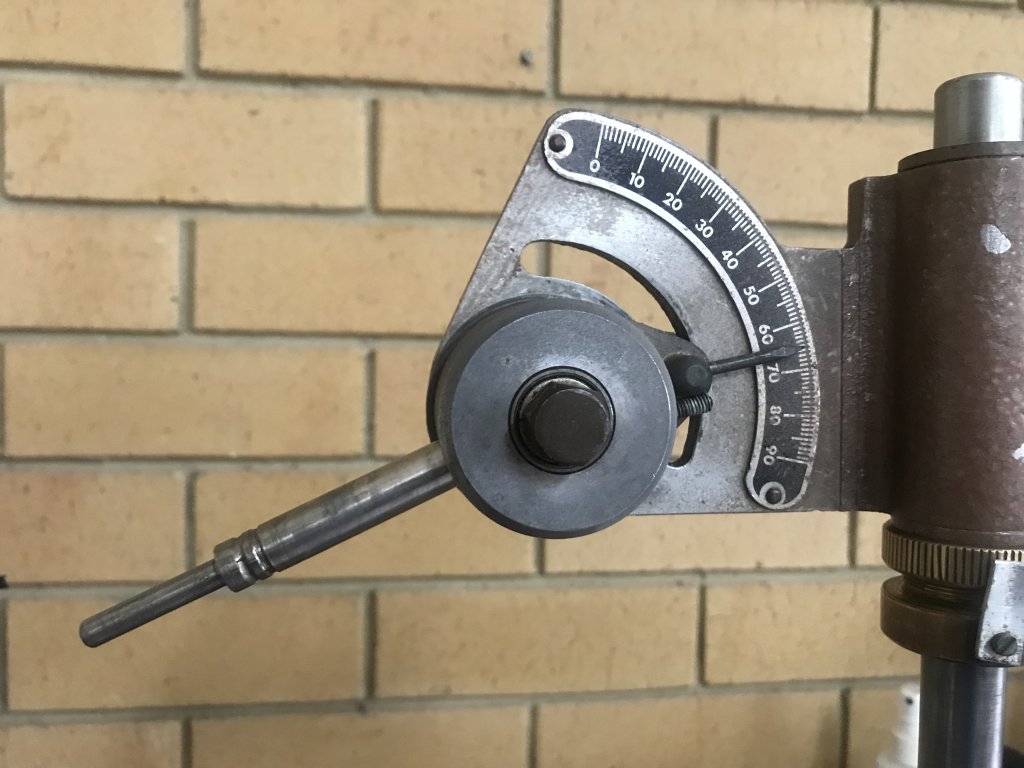

Index 32.

Index 64.

Everyone I call says in should just take this part or that part but I'm beginning to think the Gemmasta Sign on the machine doesn't include the handpiece and accompanying parts. Has anyone seen these before and have any ideas?

And stripped down further.

I'm walking in circles here so any ideas would be appreciated.

Maybe I can replace everything from the protractor through to the handpiece, but the way things are going those parts won't fit either.

Is it even a Gemmasta?

Anyway, I've had my cry. Keep on looking I guess.

Cheers.

Badge.